1. First, set the proper speed and temperature for the roll to roll heat press machine before starting. Ensure temperature stability during operation.

|

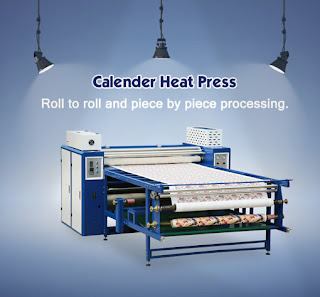

| Rotary Heat Transfer Machine |

3. Ensure the hot pressing surface, transfer paper and substrate surface must be close to, there can be no gap, otherwise it will make transfer graphics fuzzy.

4. Test before mass production to ensure proper speed and temperature.

5. Try to clean immovable items on transfer paper and textiles, otherwise the image quality will be affected.

6. Sublimation transfer paper should always be kept dry. Too much moisture affects the quality of the paper and causes many problems in sublimation printing, such as direct image skew.

7. Cut the front of the paper and fabric into an inverted V shape, then place the middle part into the oil drum heat transfer machine. It helps to stabilize the entire width while entering the hot press.

8. When you transfer, sublimation paper and textiles should be rapid separation. If not, it is easy to cause ghosting.

9.Before transfer, ensure that the basic sublimation transfer paper dry, in order to avoid incomplete transfer, stains and other phenomena.

10.Before blowing and finishing thermal transfer paper patterns and fabrics, remove the fabric and sublimation paper scraps, cilia and other attachments, so that these fragments in the thermal sublimation printing paper and fabric printing defects.

|

| Heat Transfer Machine |

12.Ghost is often due to the platen separation too fast, platen air adsorption sublimation transfer paper caused by time, should adjust the throttle to the flatbed heat press machine cylinder (or cylinder) separation speed is slow, to avoid transfer sublimation paper in the second sublimation transfer and ghosting caused by the decline of inhalation. To avoid ghosting, the sublimation paper can also be immersed in the four corners of the water adhesive cloth transfer or use sublimation paper.

13. In the process of flatbed transfer, attention should be paid to safe operation. It is strictly prohibited to put the hot plate under hands and avoid high temperature burns.

More Info:

Website: www.skyimagepaper.com

Company Name: Fei Yue Digital Technology Co.,LTD

E-mail: sales@feiyuepaper.com

Tel: 86-025-86628894

Whatsapp: +86 15007920742

Address: Central Road 323, Nanjing, Jiangsu, China

没有评论:

发表评论