|

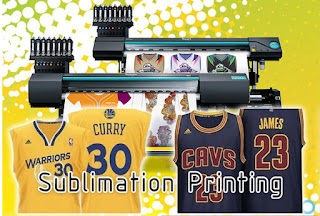

| Sublimation Transfer Printer |

What is the common phenomenon of printer cartridge leakage? How should we solve it?

During the normal use of the printer, the nozzle is tightly connected with the ink tube and the ink supply cartridge. The siphon principle is used to continuously and continuously supply ink to the nozzle during the printing process of the photo machine to ensure the inkjet printing of the nozzle. The performance of the printer when the air is leaking, for example, the photo machine will not bubble into the print head during the process of printing, the phenomenon of air bubbles flowing backward, the ink accumulation in the nozzle hole is very serious, and the contact zone will be stained with ink. There will be broken ink, etc. These are relatively obvious air leaks related to the poor ink supply of the photo machine. In this case, it may be caused by air leakage of the ink cartridge, or the seal at the elbow interface or the related ink supply tube is broken. Please check the sealing condition of the interface between the ink injection connections, the ink cartridge interface, and the ink bag. You can also remove and reconnect these interface connections to avoid looseness at the interface affecting the sealing of the connection.

|

| Sublimation Printer |

Similarly, the poor sealing of the ink supply pipeline of the digital textile sublimation printer also causes the problem of ink dripping in the photo machine, especially during printing, which directly affects our printing quality. Therefore, in the daily use of the photo machine, we must pay attention to the tightness of the ink supply pipe of the photo machine. To ensure the tightness of the ink supply piping system connection, check the ink storage tube cap and tighten it to ensure that there is no loosening, or reinforce the sealing nozzle and pin connection port to avoid loosening. At the same time, when adding maintenance operations such as adding ink to the photo machine, pay attention to the correct ink filling operation, and follow the ink filling operation instructions provided by the photo machine manufacturer. Pay attention to the standard storage ink volume of the ink cartridge. Generally, the ink capacity is 2/3 of the best. Do not make the ink volume of the ink cartridge full or low.

In addition, during the use of the printer, if you find that the related ink supply tubes, ink cartridges, and ink sacks are leaking, please replace them in time to keep the photo machine at the best-uninterrupted ink supply status at all times. Print out a more perfect picture.

More Info:

Website: http://www.sublimationstar.com/

Company Name: Fei Yue Digital Technology Co., LTD

E-mail: sales@feiyuepaper.com

Tel: 86-025-86628894

Whatsapp: +86 15007920742

Address: Central Road 323, Nanjing, Jiangsu, China