The dye sublimation paper is a type of heat transfer printing paper which functions as a carrier during the transfer of the pattern. The sublimation transfer printing first uses special inkjet printing to print a special printing dye (ink) onto the transfer paper, and then the transfer paper printed with the pattern and pattern is in close contact with the fabric, and the transfer printing is performed at 200~230 °C. The machine is processed for 10~30s, and the dye is transferred from the printing paper to the fabric, and diffused into the interior of the fabric to achieve the purpose of coloring.

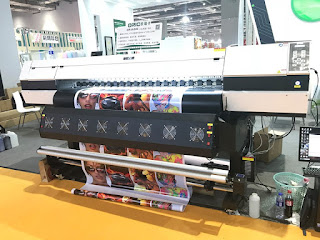

Sublimation transfer printing prints images on paper through high-speed, high-quality inkjet printers, eliminating the need for plate making, replacing screen

printing, and the patterns can be scanned by computer or scanning instruments, which is convenient, precise and easy to adjust. At the same time, the transfer pattern is clear, realistic, and the authenticity rate is high. The image is not easy to fade, fall off, and has a long service life. The printed product is soft and comfortable, and is more and more popular.

|

| Dye Sublimation Paper |

It is precisely because of its excellent performance that the

digital sublimation paper must meet various requirements, such as high temperature resistance, shape stability and ink absorption, etc., especially the ink absorption performance has a sublimation inkjet paper. Great impact. The ink absorption of the base paper is too strong. If the ink absorption is too fast, it will cause bleed, and the ink absorption is too weak. If the ink absorption is too slow, the ink accumulation phenomenon will occur. These two phenomena will affect the thermal sublimation transfer. The performance of the paper, which in turn affects the transfer effect. Therefore, it is necessary to discuss the influencing factors of the ink absorption performance of the sublimation printing paper.

1. Influence of ink viscosity on ink absorption performance

The ink absorbing performance is not only related to the structure of the inkjet sublimation paper, but also to the viscosity of the ink itself. The viscosity of the ink is too small, the penetration is strong, and it is easy to penetrate the paper to produce a tinge phenomenon; the viscosity of the ink is too large, the penetration is weak, and it is easy to accumulate on the surface of the paper to produce a pile of ink. Both twilight and ink accumulation can have a serious impact on the transfer effect of the product, and such phenomena must be prevented during the production process. Specifically, the process parameters of printing pressure, temperature and time can be combined to determine the viscosity of the ink to ensure the printing quality of the pattern.

2. Influence of paper surface coating on ink absorption performance

Since the production process of the

sublimation transfer paper is subjected to a high temperature environment, the strength performance of the paper is greatly lost, so it is necessary to increase the speed of inkjet printing and drying, and shorten the time the paper stays in a high temperature environment, so as to retain the sublimation as much as possible. The strength properties of the transfer paper meet the requirements of the product. This puts higher requirements on the ink absorbing performance of the paper. Under the condition of ensuring a certain amount of ink absorption, it is necessary to enhance the ink absorbing performance of the paper and increase the ink absorbing speed of the paper.

To this end, a layer of paint is applied to the surface of the paper as a coating to achieve rapid ink absorption. In order to meet the requirements of the national environmental protection policy, the inks currently used for the production of sublimation transfer paper are mostly water-based inks. Most of the ink components are alcohols and polyamide compounds. In order to ensure the quality of the transfer pattern, it is required that the surface coating layer does not contain a component capable of reacting with the ink used, and the coating of the surface coating layer is usually made of silicone or polyvinyl acid.

3. Influence of paper structure on ink absorption performance

The ink absorption of paper refers to the ability of the paper surface to receive the

|

| Sublimation Paper |

transfer ink at the moment of imprinting, the ability of the paper surface to be wetted by the printing ink, the ability of the paper surface to absorb certain ink components, and the ability of the paper surface to fix and retain a uniform ink film. The comprehensive embodiment. Paper absorption ink is divided into two stages, one is the pressure infiltration stage: at the moment of printing press imprinting, depending on the printing pressure, part of the ink transferred to the surface of the paper, including pigments, binders, etc., is simultaneously pressed into the paper. In the pores. The second is the stage of free penetration. This stage is from the paper leaving the embossing area until the ink is completely dry, mainly relying on the capillary action of the paper fibers to absorb the ink. At this stage, the absorption rate of the ink on the paper determines whether the printed matter has gloss, and whether powdering or offsetting occurs.

Paper is a porous material with a large number of small gaps or pores inside the paper. If the paper's pore structure and ink characteristics do not match, it will lead to a series of printing failures. When the pores between the paper fibers are small, the capillary action of the fibers is destroyed, the ink absorption performance will be poor, and when the pores are large, the ink absorption of the paper is too strong, and if the ink used at this time is low in viscosity, When the printing pressure is large, the ink will penetrate into the back of the paper, and the offset phenomenon will occur, so that the print cannot exhibit the desired color saturation on the surface of the paper, which affects the quality of the printed matter.

In addition to the basic requirements of general

coated sublimation paper, the base paper of the sublimation transfer paper has certain requirements on the tightness and air permeability of the base paper. The base paper has a tighter degree,generally above 0.9g/cm3, and the air permeability is smaller. If the base paper is too tight and has a large air permeability, the ink will penetrate into the back side of the base paper during the inkjet process, causing a bleed phenomenon. During the sublimation transfer process, the sublimated ink will also spread out through the back side of the base paper. , affecting the transfer effect. If the base paper is too tight and the air permeability is small, in the inkjet process, the ink does not easily enter the inside of the paper, accumulates on the surface of the paper, is easily smeared, and causes ink accumulation, which also affects the transfer effect. The ink absorption performance of the sublimation transfer paper base paper is also closely related to the paper void ratio, the filling amount, the sizing amount, etc., and the void ratio is a fundamental factor affecting the ink absorbing performance of the paper, and the ink particles enter the paper inside through the gaps.

The size of the void ratio directly affects the speed at which the paper absorbs ink and the amount of ink absorbed. The amount of filling will affect the void ratio of the paper, which will affect the ink absorption performance of the paper. The type of filler will be different, and the affinity for the ink will be different, which will also affect the ink absorption performance of the paper. Whether it is in-sizing or in-slurry sizing, it will affect the hydrophilicity of the paper, which will affect the absorption of ink by the paper.

4. Influence of other factors on the ink absorption performance

In addition to the above factors, the ink absorbing performance of the

heat transfer sublimation paper is closely related to the moisture content of the paper, the pressure during printing, the temperature, the time, and the like. The paper fiber is a hydrophilic substance. When the water content of the paper is high, a hydration layer is formed on the surface, which is disadvantageous for the ink binder to be combined with the fiber, and even affects the penetration of the binder, so that the absorption of the ink by the paper is lowered. Especially for oily inks with water repellency, this effect is more prominent. At the same time, the presence of the hydration layer also hinders the absorption of oxygen by the paper, delaying the process of oxidative polymerization of the ink, which is extremely disadvantageous for the absorption of ink on the paper sheet (especially the oxidized conjunctival drying type ink). Therefore, the water content of printing paper should not be too high. Taking into account other factors, the moisture content of the paper before printing is generally controlled at 4% to 8%. In addition, the printing pressure, temperature and time will also affect the ink absorption performance of the sublimation transfer paper. The printing pressure directly affects the pressure infiltration phase of the paper absorption. The temperature affects the viscosity of the ink and the drying speed of the ink. It also affects the length of pressure and temperature contact with the paper. In the actual production process, these factors must be comprehensively considered, and the production and printing process parameters should be reasonably determined to obtain qualified sublimation transfer paper.

More Info:

Website: www.skyimagepaper.com

Company Name: Fei Yue Digital Technology Co.,LTD

E-mail: sales@feiyuepaper.com

Tel: 86-025-86628894

Whatsapp: +86 15007920742

Address: Central Road 323, Nanjing, Jiangsu, China