1. When moving the uv flatbed printer, be careful not to carry the printing platform to move. To lift the bottom of the machine, you can use both hands to hold the casing to realize the mobile flatbed printer.

|

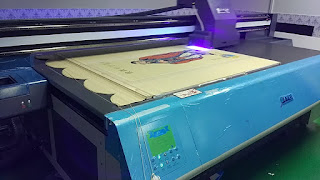

| UV Flatbed Inkjet Printer |

3. The way to add ink to the flatbed printer. Generally speaking, there are two types of ink supply methods for flatbed printers. One is a separate ink cartridge and two are continuous ink supply systems. However, the two ink supply systems have a complete set of similar working components, ink cartridges, nozzles, and cleaning units. , ink guide tube, waste ink bottle. In the case of ink refilling or in the case of an ink tube, you can use an ordinary medical syringe to pump air at the bottom of the cartridge until ink enters the syringe, or the ink is drawn from the ink tube on the waste ink bottle.

4. UV flatbed printing machine height adjustment. Generally, flat-panel printers that are popular in the market mainly detect the height of objects by infrared rays. Before the printing instructions are issued, the objects should be placed first. If the surface of the printed items has irregularities, it is necessary to pay attention to adjusting the height of the nozzles and printed products in order to avoid Crashed the nozzle.

5. Eliminate static electricity, generally the current manufacturers have not noticed, in fact, static electricity sometimes causes great damage, you can connect an external wire in the metal case, the external wire can be grounded.

|

| UV Flatbed Printer |

7. The printed picture has streaks. If the printed product has streaks, there are generally 2 possibilities. On the one hand, the 2 items storing the data are dirty. On the one hand, the nozzle may be bumped or the nozzle is blocked.

8. The nozzle drops ink. When this happens, the printed products will be mostly defective. There are two possibilities in this case. One is that the rubber ring of the cleaning unit is not sealed well, and the other is After the nozzle is hit, ink droplets gather at the bottom of the nozzle. In the first case, it is OK to change the rubber seal. In the second case, you need to use a cotton ball to wipe the bottom of the nozzle.

Therefore, the uv printer must be pay attention to daily maintenance,because it is too expensive.

More Info:

Website: www.skyimagepaper.com

Company Name: Fei Yue Digital Technology Co.,LTD

E-mail: sales@feiyuepaper.com

Tel: 86-025-86628894

Whatsapp: +86 15007920742

Address: Central Road 323, Nanjing, Jiangsu, China

没有评论:

发表评论