What are the advantages and disadvantages of these two machines?

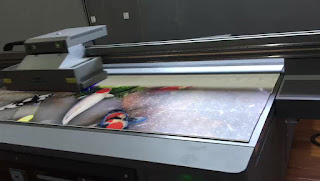

1.Advantages of the universal printer:

(1). One-off printing, no plate making, no need for film, low cost, and small-volume product printing.(2).Do not pick the material, print any material, and have good compatibility.

(3).Multi-color printing, no color registration, perfect color transition, amazing printing effect.

|

| UV Printing Machine |

(5).Fine, multi-color, special-shaped products are preferred for printing.

(6).Put the printed materials directly on the platform, you can print directly, just as the printer prints on paper is as convenient as possible.

(7).energy saving, flat panel printer only needs 220V voltage

(8).The material can print up to 15 cm in thickness, and the printing thickness can be adjusted freely (can be increased according to requirements)

(9).The platform of UV flatbed printer can withstand 50 kg material printing at a time

(10).All quantities of objects are printed successfully in one shot area

(11). uneven material (with an uneven depth of 5 mm) can be directly printed

(12).can perfectly reflect the hand-painted effect

(13).can perfectly reflect the transition color (gradient color)

2.Advantages of UV printers

(1). High color saturation and good color effect.( 2).The print has high gloss and beautiful appearance. Matching with the matte background color, you can get an exciting visual contrast, which is very helpful for enhancing the high quality image of the product.

(3). It is suitable for many kinds of printed materials with different physical properties and chemical properties, including paper, cardboard, plastic, racetrack, PVC, PE, etc. This feature can print more product types than traditional lithography, and has a broader market future.

(4). It can be dried immediately at the same time of printing, which can greatly improve production efficiency. Since there is no need to wait for the ink drying time, the production time can be greatly shortened, and the printing company can save a lot of space for storing the to-be-printed parts, which is helpful for cost saving.

|

| UV Printer |

(6). Since it is dry immediately after printing, it can not be like the traditional lithographic printing, color change will occur within 48 hours of printing.

(7). The print is more resistant to light.

(8). The abrasion resistance of the print is better.

(9). More affinity for the environment

3.Disadvantages of UV printers compared to universal printers

Fast speed,the speed of the UV inkjet printer is 9-10 square meters per hour.The normal working speed of the universal printer is 3-4 square meters.4.Disadvantages of UV printers compared to universal printers

(1) High barriers to entry: high machine prices, high maintenance costs, and UV ink prices are much higher than traditional inks.(2) Long preparation time: As with the copier, it needs to be preheated, about 30 minutes, and it costs more.

(3) Printing media is not resistant to high temperature: it can't be blistered, and it will fall off easily after high temperature.

(4) Short print head life: Due to the long-term UV curing, it is inevitable that some light sources will reflect/refractive to the nozzles, and the nozzles will solidify together. It can only be replaced.

(5) There is a certain danger: UV light is harmful to human skin and eyes, and ozone generated by ultraviolet radiation is also harmful to the human body.

(6) As the temperature changes, the medium will expand and shrink, and it will fall off easily. For example: glass, ceramic tiles, etc.

(7) UV light curing can only reach about 75% at present, which means that although the surface is dry after the screen is finished, the actual internal is not completely dry, which also causes cracking and falling off after a period of time.

(8) In actual production, the printing speed of the machine will also affect the quality of UV curing.

(9) UV ink storage is inconvenient, because UV ink is easy to deteriorate after seeing light, and it cannot be used normally after curing.

|

| UV Inkjet Printer |

(11) Large format UV printer cost and consumable cost are much cheaper than UV, especially when using UV mode nozzle is very expensive,it is not very cost-effective when making a single order.

More Info:

Website: www.skyimagepaper.com

Company Name: Fei Yue Digital Technology Co.,LTD

E-mail: sales@feiyuepaper.com

Tel: 86-025-86628894

Whatsapp: +86 15007920742

Address: Central Road 323, Nanjing, Jiangsu, China

没有评论:

发表评论