Sometimes the photo sublimation printer will suddenly be damaged when printing. Do you know why this is happening? Here are some relevant reasons for your reference.

1.There is air in the pipe

|

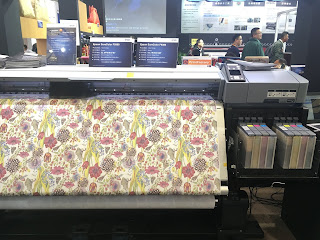

| Photo Sublimation Printer |

For the

sublimation printing machine, the contact point between the pipe and the ink head is loose or the ink head leaks, causing the ink to flow back to the left ink supply bin, causing the ink head to be burned. If bubbles are contained in the process of filling the ink, the general burning will cause a short circuit, thus causing the entire group of nozzles to fail. For Epson F6200,F7200,F9200 printing machines, too much air is injected when the ink tank is filled instead of ink. When the air bubbles cause insufficient ink supply in the ink head, the heating element will not have enough ink. It is cooled to cause the heated wafer to overheat and burn, causing damage.

2. Static interference

An overly dry working environment will directly generate a large amount of static electricity, which directly causes damage to the ink head circuit. Or when using printed materials, especially when using plastic-based materials such as PP and backing media, it will generate a large amount of static electricity; damage the ink head or Causes the accumulation of impurities to cause damage to the ink head.

3. External voltage

Excessive or unstable external voltage can have a significant impact on the print head, instead of the print head, which can cause the machine to burn out the print head or not recognize the print head.

4. Do not pay attention to operation and maintenance

|

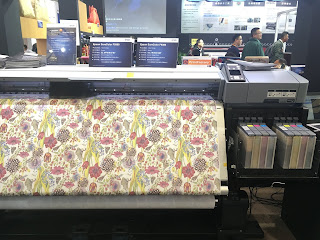

| Sublimation Printer |

For the Epson series of print heads, the direct cause of damage

inkjet sublimation printer is physical damage, that is, due to the media curling of the paper, etc., the metal hole on the bottom of the print head is scratched during the printing process, causing the print head orifice to be damaged and unable to be sprayed normally. The ink head maintenance station on the right side of our machine and the cleaning box on the right side of the machine should be taken off frequently and cleaned with pure water to prevent the ink head from clogging due to too much ink accumulation. If there is too much ink on the bottom of the Epson 9200 ink head, it will also block the printing nozzle hole, and it should be removed and cleaned with warm water.

5. Ink quality

The ink contains a variety of chemical components, often due to factors such as poor filtration, high viscosity, and poor moisturizing liquid, causing the print head to malfunction.

More Info:

Website: www.skyimagepaper.com

Company Name: Fei Yue Digital Technology Co.,LTD

E-mail: sales@feiyuepaper.com

Tel: 86-025-86628894

Whatsapp: +86 15007920742

Address: Central Road 323, Nanjing, Jiangsu, China

没有评论:

发表评论